Medical Packaging

Medical packaging, like all other packaging, is designed to get a product from one place to another. Whether it is from a manufacturing plant to the surgical floor or the local pharmacy to a patient’s door. The difference is the standards that the medical packaging must adhere to. Medical packaging must be airtight and watertight and keep contaminants to the absolute minimum. There is a whole industry that has been built around medical packaging and its job is to make sure that the packaging lives up to the standards that are set forth by the FDA. Unfortunately, much of the medical packaging used is one-time-use plastic. Over 5.9 million tons of medical waste is produced every year, and that’s in the US alone. Below, are two pictures that show medical packaging and medical packaging waste. Pictured left is what we are used to seeing in every medical evaluation room in the US and pictured right is what we don’t realize, it all gets thrown away.

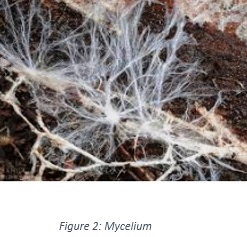

This is the reality of the medical packaging industry. The picture to the left is what we expect from all the regulations and standards of medical packaging and to the right is the aftermath. Decades and billions of dollars have been spent on creating an unsustainable plastic-producing industry. While we feel safe and sanitary in the hospitals, we also feed the ever-building mounds of single-use plastic that have been slowly spreading not only across our country, but around the globe. There might be a way out, a way to reduce our reliance on plastic without giving up the protection of sterilized medical packaging. The answer – mushrooms - or Mycelium to be more precise.

Mycelium as medical packaging

Mycelium (see figure 2) is the underground root system of fungi. As a product, “mycelium is a bio-engineered form of hyphae that are made from agricultural waste mixed with these root-like structures as binding agents” (Flagel). Right now, the most common commercial application of mycelium is in fact packaging. It can be used to replace Styrofoam and other extruded polystyrene products. Agricultural waste is broken down, sterilized, seeded with mycelium, pressed to form, and then left to sit for a couple of days. When the colonization is complete, the form is heated to stop the growth and then cooled again to form the packaging. The forms are impact, moisture, and fire resistant. It can be used for insulation (see figure 3) to keep items cool or in any other way that you could think of using packaging material. The best part about it is that it is 100% biodegradable.

This type of packaging is great to use to send a TV across the country, but what about a knee replacement or surgical instruments? Research is already underway on ways to use mycelium as a base material to grow organs. So, it is safe to say that if it is sterile enough to put in your body it must be good enough to ship medical products in.

Pros of Mycelium

Although the technology is new, it does already exist and there are already many companies putting the time and money into developing faster and cheaper ways of producing mycelium products. Once the products are made, they are 100% biodegradable. No landfill is needed because, depending on the process used to make the specific forms, it can take as little as 30 days for the packing materials to return to nature with zero negative effects. When it returns to nature, it becomes a source of nutrients. Imagine getting your prescription in the mail and being able to throw away most of the packaging in your backyard. It is also a 100% renewable resource. There is no need to worry about how much material you use because you can make more. Imagine cutting the 5.9 million tons of medical waste in half and then in half again and keep going until there is no more medical waste. People can feel safe going to the hospitals and feel good knowing they did not contribute to the single-use plastic pandemic (see figure 4).

Cons of mycelium as medical packaging

It is always nice to know that there is a way to fix the negative impacts we have done to the world without any downside. Unfortunately, there is always a downside. As far as mycelium uses in medical packaging, it is still a budding technology, and it is not an overnight fix. Right now, the cost of using mycelium as a packaging material is not cost prohibitive, but it is still not as cheap as making plastic, which might change over time. The good news is that most people are willing to pay the extra it will cost for the zero environmental impact. Mycelium forms take time to make, as mentioned before, it’s a new technology and the manufacturing infrastructure is not yet in place to keep up with demand. There are many questions that still do not have answers such as the following: Once the infrastructure is in place, will it still be able to keep up with demand? The agricultural waste must come from somewhere. What happens to the industry that is already in place? Will that industry just roll into the new one? What happens to all those jobs? It is hard to fix one problem without possibly causing a new one. That is often what happens. We as humans, work so hard to fix a problem today that we don’t think about the impact it will have 10 years down the road.

References

Blessy Joseph, Jemy James, Nandakumar Kalarikkal, Sabu Thomas. "Recycling of medical plastics." 28 July 2021. Science Direct. Article. 01 May 2022.

Delamatta, Lydia. "Can Mushrooms Eliminate Plastic?" 1 December 2021. sdg.iisd.org. Document. 01 May 2022.

Flagel, Jordan. "Mycelium: Using Mushrooms to Make Packaging Materials." 03 April 2020. Matmatch.com. Document. 1 May 2022.

Kanojia, Monica. "Eco-friendly Company Introduces Nature’s Packing Peanuts." 11 December 2012. National Science Foundation. Article. 01 May 2022.

Libin Yang, Daekwon Park, Zhao Qin. "Material Function of Mycelium-Based Bio-Composite: A Review." 30 September 2021. Frontiers in Materials. Article. 01 May 2022.

Marah Trabelsi, Al Mamun, Michaela Klocker. "Polyacrylonitrile (PAN) nanofiber mats for mushroom mycelium growth investigations and formation of mycelium-reinforced nanocomposites." 30 September 2021. Sage Journals. Article. 01 May 2022.

Overstreet, Sarah. "INFOGRAPHIC: 10 Things to Know About Medical Waste Compliance." 8 January 2018. Sharps Compliance, inc. Artical. 01 May 2022.

Reyes, Justin. "Nature’s polymer for packaging, insulation, and more." 10 July 2013. Mycopia. Article. 01 May 2022.